Argomenti trattati

3D printing is advancing at an incredible pace, and some of the most exciting innovations are coming out of the Massachusetts Institute of Technology (MIT). Their latest breakthroughs in glass manufacturing are truly game-changing, proving that the possibilities for 3D printing are expanding every day. But why is this development so significant? Let’s dive into what it means for the future of glass products.

The challenges of traditional glass manufacturing

Creating glass products has always been a tricky endeavor. Traditional methods require extreme temperatures for shaping and annealing the glass, making the entire process energy-intensive and complicated. Typically, the glass must be heated to its melting point, which limits the complexity of the designs that can be achieved. Doesn’t that sound like a major hurdle for designers?

On top of that, traditional glass manufacturing methods can be inflexible, leaving designers feeling restricted by a narrow range of shapes and sizes. This rigidity can be a real setback for industries that rely heavily on glass components, such as electronics and fluid systems. Imagine how many innovative designs could be realized if these limitations were lifted!

MIT’s innovative approach to 3D printing with glass

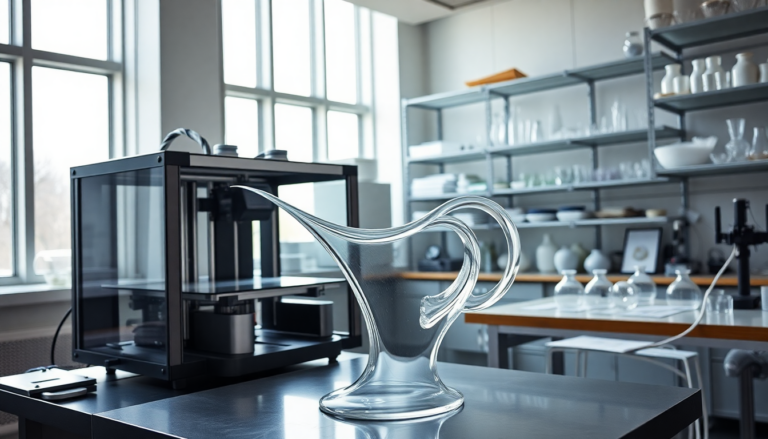

Enter the team at MIT, who have risen to the challenge with a groundbreaking technique that allows for 3D printing of glass at significantly lower temperatures. This new method, known as low-temperature additive manufacturing, uses an inorganic composite glass filament made from nanoparticles and silicate solutions. This innovative material not only maintains the necessary structural integrity but also solves many of the stability issues that plague traditional glass filaments.

After the glass filament is printed, it undergoes a post-processing phase where it’s placed in an oil bath and heated to a controlled temperature of 250°C. This step is crucial; it enhances the stability and quality of the printed glass while allowing for the removal of any residual materials with an organic solvent. The end result? A robust glass structure that can be molded into intricate designs that were once thought impossible.

Future implications and potential applications

The implications of this breakthrough are thrilling and extend far beyond mere novelty. The ability to produce complex glass components with precision opens up a host of possibilities across various industries. For example, consider high-temperature electronic components that require glass for insulation or protection—they could now be manufactured more efficiently and with greater accuracy. And let’s not forget about microfluidic systems, which are vital for biotechnology and pharmaceutical applications. This new 3D printing technology could provide the flexibility and customization these fields desperately need.

While it might take some time before glass filaments hit the commercial market, MIT’s ongoing research and development indicate a bright future for additive manufacturing in glass. As these advancements continue, we may soon see industries embracing this technology, leading to innovative products that were once viewed as unattainable.

In conclusion, MIT’s pioneering work in 3D printing with glass is not just breaking down barriers in traditional manufacturing; it’s paving the way for a new wave of innovation. With the potential to revolutionize how we think about glass products and their applications, this technology is a shining example of how creativity and science can come together to create something extraordinary. Are you ready to see where this journey takes us?