Argomenti trattati

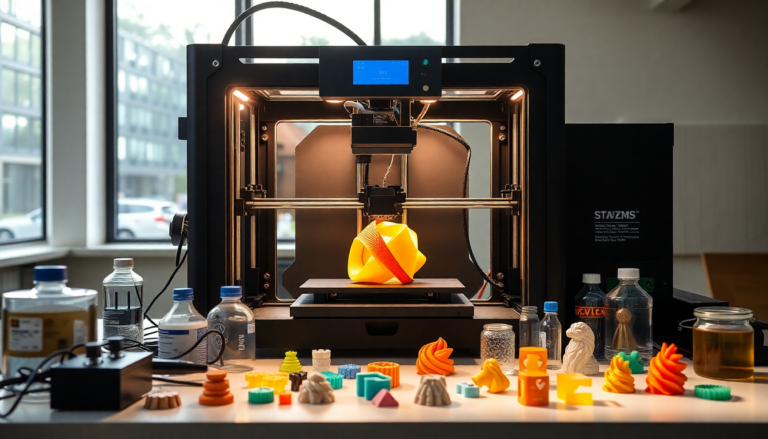

Recent advancements in 3D printing technology have opened exciting new avenues for material creation. One standout development comes from the University of Texas at Austin, where researchers have introduced a groundbreaking technique that enables the simultaneous printing of both hard and flexible materials using a single type of resin. This innovation is set to significantly broaden the horizons of additive manufacturing.

Introducing the Dual-Light Printing System

Meet the dual-light printing system—an ingenious process that utilizes a custom UV printer. This printer emits different wavelengths of light, allowing for the creation of materials with varying degrees of hardness. Imagine printing hard and soft components together as one cohesive unit, eliminating the need for separate bonding processes after printing. With concentrated violet light, the soft, flexible material takes shape, while robust structures are formed using strong UV light.

This remarkable combination not only streamlines production but also enhances the functional capabilities of 3D printed objects. Just think about it: what if we could integrate diverse material properties into a single printed item? The possibilities are endless!

Potential Applications and Use Cases

The implications of this dual-material printing technique are vast and varied. A captivating demonstration video showcased the ability to replicate a human knee, illustrating how rigid bone structures can support flexible ligaments, effectively mimicking natural movement. This capability opens the door to transformative applications in the medical field, particularly in designing and fabricating prosthetics that require both flexibility and strength.

But that’s not all—this technology could also lead to significant advancements in the design of electronic devices. Imagine stretchable components that maintain the integrity of internal wiring! The potential to create multifunctional objects—from toys to advanced medical devices—highlights the versatility of this innovative printing method. Isn’t it fascinating to think about the wide range of products that could emerge?

The Future of 3D Printing Technology

While this technology is still in the research phase and not yet commercially available, the excitement surrounding its potential is palpable. As the field of 3D printing continues to evolve, we can look forward to a future where such advancements become integral to various industries, from healthcare to consumer products.

For those of you exploring the world of 3D printing or looking to deepen your understanding, now is the perfect time to dive in. As the barriers between hard and soft materials continue to blur, the future of 3D printing promises to be as dynamic and multifaceted as the materials it will produce. Are you ready to explore this fascinating frontier?